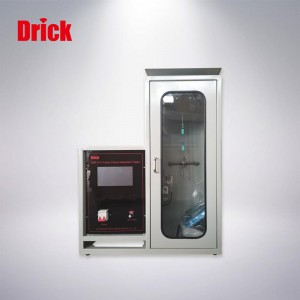

DRK-07A Flame Retardant Tester bakeng sa Liaparo tse Sireletsang

Lintho tsa liteko: Fumana tšekamelo ea masela ho tsoela pele ho chesa, ho kubella le ho etsa carbonization

DRK-07AFlame Retardant Testerbakeng sa liaparo tse sireletsang, tse sebelisetsoang ho fumana tšekamelo ea masela ho chesa, ho tsuba le ho chesa. E loketse ho etsa qeto ea thepa e thibelang malakabe ea masela a lohiloeng a thibelang mollo, masela a lohiloeng le lihlahisoa tse koahetsoeng.

Lintlha tsa Sehlahisoa:

1. DRK-07A liaparo tse sireletsang lelakabe retardant tester maemo a ho sebetsa le matšoao a sehlooho botekgeniki

1. Mocheso oa tikoloho: -10℃~30℃

2. Mongobo o amanang: ≤85%

3. Matla a phepelo le matla: 220V±10% 50HZ, matla a ka tlase ho 100W

4. Pontšo/taolo ea skrine ea ho ama, liparamente tse amanang le skrini:

a. Boholo: lisenthimithara tse 7, boholo bo sebetsang ba pontšo ke 15.5cm ka bolelele le 8.6cm ka bophara;

b. Qeto: 800 * 480

c. Khokahano ea puisano RS232, 3.3V CMOS kapa TTL, boema-kepe ba serial

d. Bokhoni ba polokelo: 1G

e. Sebelisa lisebelisoa tse hloekileng tsa FPGA ho khanna pontšo, "zero" nako ea ho qala, 'me e ka sebetsa ka mor'a ho bulela

f. Adopt M3 + FPGA meralo, M3 e ikarabella bakeng sa tlhahlobo ea litaelo, FPGA e shebane le ponts'o ea TFT, lebelo le ts'epahalo li etella pele tharollo e ts'oanang.

g. Mookameli ea ka sehloohong o nka li-processor tse fokolang matla 'me o kena ka mokhoa o itekanetseng oa ho boloka matla

5. Nako ea lelakabe la kopo ea mollo oa Bunsen e ka behoa ka mokhoa o ikemetseng, ka ho nepahala ha ± 0.1s.

6 Bunsen burner e ka sekamisoa ho tloha ho 0-45 °

7. Bunsen burner high-voltage automated ignition, nako ea ho khantša: e behiloe ka boikhethelo

8. Mohloli oa khase: Khetha khase ho ea ka maemo a taolo ea mongobo (sheba 7.3 ea GB5455-2014), boemo ba A bo khetha propane ea indasteri kapa butane kapa propane / butane e tsoakiloeng ea khase; boemo B bo khetha methane e nang le bohloeki bo seng ka tlase ho 97%.

9. Boima ba boima ba sesebelisoa: 40kg

DRK-07A liphahlo tse sirelletsang lelakabe retardant tester karolo selelekela selelekela

1.Ta——nako ea ho sebelisa lelakabe (o ka tobetsa nomoro ka ho toba ho kenya sebopeho sa keyboard ho fetola nako)

2.T1——Ngola nako ea lelakabe le tukang tekong

3.T2——Rekota nako ea ho tuka ho se nang mollo (ke hore, ho kubella) tekong

4. Qala-tobetsa mollo oa Bunsen ho fallela sampole ho qala tlhahlobo

5. Emisa-secheso sa Bunsen se tla khutla ka mor'a ho tobetsa

6. Khase e hatelloang ke khase ho bulela

7. Ignition-tobetsa ka makhetlo a mararo ho hotetsa ka boits'oaro

8. Nako ea ho rekota-T1 e emisa ka mor'a ho tobetsa, 'me ho rekota ha T2 ho emisa hape ka mor'a ho tobetsa

9. Boloka-boloka data ea hajoale ea tlhahlobo

10. Phetoho ea boemo-e sebelisetsoang ho lokisa boemo ba mollo oa Bunsen le mokhoa

Taolo ea Mongobo oa Mohlala le ho Omisa

Boemo A:Mohlala o behiloe tlas'a maemo a tloaelehileng a sepakapaka a boletsoeng ho GB6529 ho lokisa mongobo, ebe sampole e nang le mongobo e kenngoa ka sejaneng se tiisitsoeng.

Boemo B:Beha mohlala ka ontong ka (105±3) ° C bakeng sa (30±2) min, e ntše,' me ue behe ka har'a setlolo hore se phole. Nako ea ho pholile ha e ka tlase ho 30min.

'Me liphetho tsa boemo ba A le boemo ba B ha li bapisoe.

Tokisetso ea Mohlala

Lokisetsa lisampole ho latela maemo a taolo ea mongobo a boletsoeng likhaolong tse kaholimo:

Boemo A: Boholo ke 300mm * 89mm, likotoana tse 5 ka tataiso ea warp (longitudinal) le likotoana tse 5 ka tataiso ea weft (transverse), kakaretso ea disampole tse 10.

Boemo B: Boholo ke 300mm * 89mm, likotoana tse 3 ka lehlakoreng la warp (longitudinal) le likotoana tse 2 ka lehlakoreng la latitude (ho rapama), kakaretso.

Boemo ba mohlala: Ha u khaola sampuli, sebaka se tsoang moeling oa lesela ke bonyane 100mm. Mahlakore a mabeli a sampuli a tšoana le tataiso ea warp (longitudinal) le tataiso ea weft (transverse) ea lesela ka ho latellana. Bokaholimo ba sampole e lokela ho ba ntle le matheba le wrinkles. Mehlala ea Warp e ke ke ea nkuoa khoeleng e tšoanang ea warp, 'me lisampole tsa weft li ke ke tsa nkuoa khoeleng e tšoanang ea weft. Haeba sehlahisoa se lekoa, seams kapa mekhabiso e ka kenyelletsoa sampuling.

Phethahatso ea Maemo

ASTMF6413: Mokhoa o tloaelehileng oa tlhahlobo bakeng sa ho lieha ha lelakabe la masela (teko e otlolohileng)

GB/T 13489-2008 "Qeto ea Ts'ebetso e Chesang ea Lesela le Apesitsoeng ka Rubber"

TS EN ISO 1210-1996 "Qeto ea litšobotsi tse tukang tsa polasetiki mefuteng e otlolohileng e amanang le mohloli o monyane oa ho tima"

Liaparo tsa tšireletso tse thibelang mollo*Liaparo tse ling tse thibelang mollo

Lihlopha tsa lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

-

Holimo